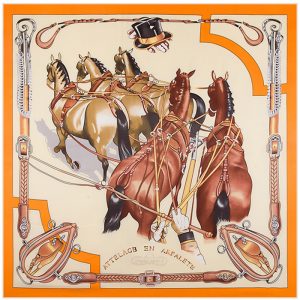

What is printing?

The printing process is a process in which a pattern is applied to a textile using a dye or pigment. The prints are divided into fabric prints, tops and yarn prints, while fabric prints. The top print is used to make mixed color tweed; the yarn print is used to weave a special style of colored pattern fabric. Fabric printing has a long history. China has applied hollow printing in the Warring States period (see Chinese dyeing and finishing history). India had a wood stencil print in the 4th century BC. Continuous gravure printing began in the 18th century (see roller printing). Screen printing is developed from the hollow version and is suitable for small batch and multi-variety printing of easily deformable fabrics.

The way the fabric is printed

1.Direct

One of the printing methods. The method of directly printing the flower patterns of various colors on the fabric is direct printing, which is the simplest and most common one of several printing methods. In the printing process, the color pastes of various colors do not hinder and destroy. About 80%-90% of printed fabrics use this method. The method can print white flowers and flower patterns. According to different pattern requirements, it is divided into white, full and color: white printing pattern area is small, white area is large; area of printed area is large, most areas of fabric are printed with pattern; direct printing of color It means dyeing the ground color first, then printing the pattern, which is called “overprint”. However, due to the color combination, the same color is generally used, and similar colors or shallow deep flowers are mostly used, otherwise the color of the overlapping color is dim.

2. Discharge

On the dyed fabric, a paste containing a reducing agent or an oxidizing agent is printed to destroy the ground color and partially expose the white or colored pattern. The dyed ground fabric is printed with a color paddle containing chemicals that can destroy the ground color. These chemicals are called discharge agents. Chemically resistant dyes can also be added to the discharge paddle. Such a discharge printing can obtain two effects, namely, whitening and color drawing.

3. Anti-dyeing

A printing paste which is first printed on the fabric to prevent the dyeing of the ground dye or color, and then dyed to obtain a printing process of the colored carpet. The substance that prevents dyeing in the printing paste is called an anti-staining agent. A white pattern printed on a printing paste containing an anti-staining agent is called a white-proof printing; in the anti-dye printing paste, a dye or pigment which is not affected by the anti-staining agent is printed with a colored pattern, which is called a color anti-printing. Firstly, the anti-dyeing agent which can prevent dye dyeing is printed on the fabric, and then the color is padded, and the pattern is printed to prevent the ground color from being dyed. This method is anti-dye printing, and the method can obtain three effects, that is, Anti-white, color and partial anti-staining.

Cleaning method

1. When using hand washing, please use a neutral detergent. (such as washing spirits, body wash, shampoo, etc.)

2, the water temperature can not exceed 37 ° C, first stir the water detergent before you can put it.

3. Do not soak in water for more than 5 minutes, gently wash and rinse with your hands, do not wring out. When cleaning, please remember to explain to the laundry that it is a silk product.

4. Remember not to use alkaline detergents such as washing powder, laundry soap, soap, etc., and can not be mixed with other colored clothing.

5. Dry the scarf and avoid drying it under the sun or fluorescent light.

6. Ironing with medium temperature steam (130 ° C – 150 ° C). It is best to fold and store, keep it dry, and the insect repellent should be wrapped with cloth. Do not touch the silk scarf or silk shawl directly.

7. If the product loses its luster after long-term use, soak the product in cool water with white vinegar (a few drops can be used) for 10 minutes, repeated several times to restore the luster.

If you want to konw more about the printed scafves,please read the blog.